Our shaft profiling system saves you strokes. How? By making sure that we have fit you to shafts that optimize your performance. We spend a lot of time analyzing shafts and their impact on the distance, accuracy and consistency of our golfers shots. After all, the shaft is the only moving part of the golf club and is the transmission that delivers energy of your swing to the golf ball.

Our shaft profiling system saves you strokes. How? By making sure that we have fit you to shafts that optimize your performance. We spend a lot of time analyzing shafts and their impact on the distance, accuracy and consistency of our golfers shots. After all, the shaft is the only moving part of the golf club and is the transmission that delivers energy of your swing to the golf ball.

When we profile a shaft, we take 24 measurements of the shaft that we have determined are important: Length, actual flex (cycle per minute), bend profile at eight locations along the shaft length, weight, balance point and torque. From these numbers we then calculate a spine index (how different the shaft is from high to low bend point), a quality index (how well all of the shafts in the same flex match each other), and a feel index (will this shaft feel firm like and extension of your arm or hinged and feel like a two piece shaft). While some of these calculations are subjective, the bottom line is that the give us a great deal of valuable data to build quality clubs for our customers. Let’s look at what we have learned:

Weight consistency: A shaft may have a gram marking like 50 or 65 which usually indicates the gram weight of the shaft. These markings can be off by as much as 10 grams either way, heavier or lighter, depending upon the shaft manufacturer. Typically heavier shafts in a range will be stiffer in flex, but not always. It depends upon their design. If shafts are not the correct weight, you may start losing consistency and accuracy.

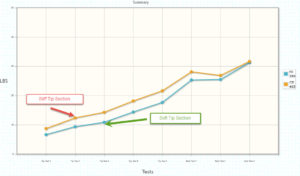

Spine Index: We have known since we started in the custom club building business that every shaft has a “spine” or location when you rotate the shaft that is the stiffest. While almost every shaft manufacturer recognizes this and have made great strides to reduce this phenomenon, shafts still have a spine. If the spine is not oriented in the direction of the target (our interpretation of how spine alignment should work), the shaft will fight to get to its normal spine location. This could lead to the club face being open or closed at impact causing errant shots. Shafts have much tighter spine index tolerances (1 – 2%) in the butt section of the shaft but the tip sections can be as much as 9-10% from high to low load. Sometimes, but not always, a less expensive shaft will have more variation. That is why it is important to have your clubbuilder spine the shafts during assembly. And be careful when rotating a shaft in an adjustable hosel…the spine can/will change!

Shaft Flex: As we have know for years, two shaft manufacturers that label their shafts “S” can have vastly different actual CPM (cycles per minute) readings. While there are naysayers that say the tight tolerances of frequency matching does not really matter in accuracy or consistency of shots, we have found that being off by 3-4 cpm’s, or roughly a half a flex can make a dramatic difference in shot dispersion. It is not just a variation by manufacturer but by product line. As an example, light weight steel shafts, under 100 grams are notorious for playing soft to the actual flex markings. In some cases as much as two flexes soft! On the opposite end are wood shafts designed for stronger swings. These shafts can actually test one to two flexes stiffer than marked on the shaft.

Shaft Bend Points and EI Curves: While every manufacturer talks about how their shafts may have a stiff butt section, medium mid section and stiff tip section, this is all relative to the way they measure those EI curves or bend profiles. Our system is very specific and measures load at 7 or 8 points along the shaft length. We then classify the shafts profiles in terms of trajectory and spin as Low, Low-Mid, Mid, Mid-High and High. We also determine a specific “feel” index that some golfers can relate to very well. Does the shaft have a feel of kick in the middle or is it more stable all the way from top to impact. It is interesting that we can have two styles of shafts that our golfer relate to that can give similar launch and spin numbers but feel completely different.

So what we do with every new shaft is identify its profile based on these static numbers and then use that information in our clubbuilding. We also have a group of testers that test these shafts to make sure they are actually what they are supposed to be (low launch, low spin, for example). By testing these shafts both statically and in dynamic testing, we can ensure that the shafts we have selected for our golfers will meet our expectations. That is also how we can guarantee performance! Bottom line, our shaft profiling saves our customers strokes!

Dan Sueltz